The Supplies you need for stone, tile, marble, concrete and more

Toll Free

866-227-8665

We accept

Cart

0

Product

Products

(empty)

No products

To be determined

Shipping

$0.00

Total

Product successfully added to your shopping cart

Quantity

Total

There are 0 items in your cart.

There is 1 item in your cart.

Total products

Total shipping

To be determined

Total

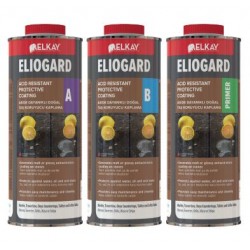

Elioguard Acid Resistant Protective Coating (3 LT KIT)

New product

More info

ELKAY ELIOGARD is a solvent based two component coating for acid sensitive surfaces.

-

100% acid resistant.

-

Forms super thin coating on the surface and protects acid-sensitive calcareous natural stones such as marble, limestone and

-

Travertine from staining, acid-etching and acid aggressions of food, drinks and cleaning products.

-

Resistant to lemon, vinegar, wine, limescale, fruit juices, coffee , oil, tea, soaps and shampoos.

-

Provides easy cleaning.

-

High UV resistance and is food contact approved.

-

Suitable for interior and exterior surfaces.

-

3 years warranty, if applied by an accredited applicator following our written instructions in our TDS.

-

Protects natural stones for long time with a one-time application from all kinds of staining.

ELKAY ELIOGARD FAST CUT POLISHING PASTE #1

-

highly effective polishing compounds for vehicle paint systems, composite materials and natural stones

-

eliminates signs of tear and wear, overspray and grit 2000 sanding marks in one step. P

ELKAY ELIOGARD HAZE REMOVER POLISHING PASTE # 2

-

highly effective polishing compounds for original /repair paint and coating systems.

-

eliminates signs of tear and wear, overspray and grit 3000 sanding marks in one step.

ELKAY ELIOGARD SWIRL MARK REMOVER POLISHING PASTE #3

-

highly effective polishing compounds for buffing, polishing, paint finishing, swirl mark removal.

-

It eliminates signs of tear and wear, overspray and grit 3000 sanding marks in one step.