The Supplies you need for stone, tile, marble, concrete and more

Toll Free

866-227-8665

We accept

Cart

0

Product

Products

(empty)

No products

To be determined

Shipping

$0.00

Total

Product successfully added to your shopping cart

Quantity

Total

There are 0 items in your cart.

There is 1 item in your cart.

Total products

Total shipping

To be determined

Total

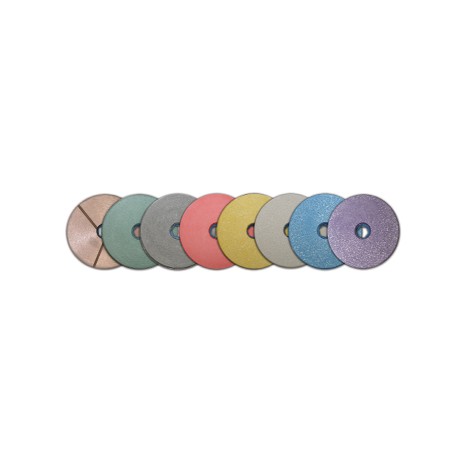

Glossfire Resin Multi Edge Discs

New product

•GlossFire™ wheels will polish all edges that the machine is capable to fabricate and optimize the productivity cycle by achieving ready-to-install countertops with a single pass.

More info

Glossfire Multi Edge Discs

-

GlossFire™ wheels will polish all edges that the machine is capable to fabricate and optimize the productivity cycle by achieving ready-to-install countertops with a single pass.

-

Designed to work with any in-line multi edge polishing machine using the popular snail lock adapter. These include Marmo Meccanica (LTH & LTT), Sasso Meccanica (TE Experience & RCM Multi head), Park Industries (Velocity), Montesor (Luna) and others.

-

We recommend using GlossFire™ copper bond tools after the metal bond shaping tools and before the resin bond GlossFire™ polishing tools. This allows for a smooth transition between metal and resin bond tools, what will extend the life of the entire tool set.

-

Available in 5 and 6 inches, in resin and copper bond (see below)

Suggested Application Data for natural stone materials:

• For 5 head machines, start with grit 200 resin and follow with grits 500, 1000, 2000 and Buff. • For 6 head machines, start with grit 100 resin and follow with grits 200, 500, 1000, 2000 and Buff. • For 8 head machines, start with grit 100 copper and follow with grit 100 resin. After that continue with 200 copper, 200 resin, 500, 1000, 2000 and Buff. • For 9 head machines, start with grit 100 copper and follow with grit 50 resin. After that continue with 100 resin, 200 copper, 500, 1000, 2000 and Buff. NOTE: Start at 30 PSI (2 bars) and increase the pressure by 5 PSI (0.3 bars) at each consequent step. For example, if you start with grit 100, you have to set the machine at 30 PSI. For grit 200 – 35 PSI, grit 500 – 40 PSI, grits 1000, 2000 and BUFF – 50PSI.

Application Data for Engineered (manmade) materials:

• For 5 head machines, start with grit 200, 400, 600 copper bonds and follow with grits 1000, 2000 resin bond. • For 6 head machines, start with grit 100, 200, 400, 600 copper bonds and follow with grits 1000, 2000 resin bond. • For 8 head machines, start with grit 100, 100, 200, 400, 600 copper bonds and follow with grits 500, 1000, 2000 resin bond. • For 9 head machines, start with grit 100, 100, 200, 400, 600 copper bonds and follow with grits 500, 1000, 2000 resin bond. You can leave one of the heads empty or double grit 200 copper bond.

Designed for:

-

Marmoelettromeccanica,

-

USG Machinery,

-

Park Industries,

-

Comandulli,

-

Sasso,

-

Breton,

-

CMPI,

-

Montresor,

-

Omega

-

And other machines.